Complete Digital Print Tower

As a unique Print Tower for digital printing, the M-Tower™ includes mountings for inkjet heads, dryers, speed encoder, cue mark sensor and guarantees optimised reliability and operability.

The M-Tower is primarily designed to complement the Matti Imprinting Solution – together, these products can be used in a multitude of ways to achieve almost any task, be it in a standalone context or inline with an offset or flexo press for personalisation or MICR printing.

The paper is typically pulled by the host system, e.g. offset / flexo printing presses or finishing lines and can run up to approx. 1000 ft/m (300m/min).

The M-Tower comes with 20.5” (520mm) or 26″ (660mm) as the standard web width. Other widths can be manufactured upon specific customer requests.

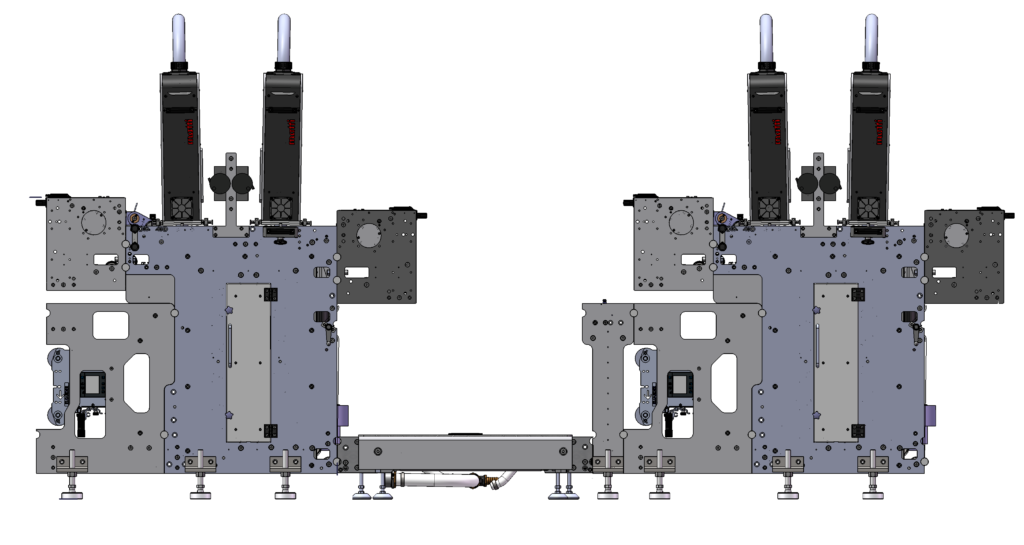

Printing on both sides of the paper requires 2 Towers / Twin-Tower configuration with a turnbar, integrated into a walk-over between the towers, as depicted above.

The design of the system is implemented in a modular way: infeed / outfeed, dryers and web guide can be installed only if the application requires.

The integrated dryer uses the latest Matti infrared technology and can be either IR at around 2.1 microns wavelength or NIR with typically a lower wavelength.

Precisely manufactured Inkjet head mounts guarantee perfect stitching and alignment of each head and are available for all common sizes of printheads and Matti printbars. Depending on the number of heads installed, there are various means to access them for easy cleaning and inspection.

Possible Configurations

Different applications need different M-Tower configurations:

Standalone press, combined with Matti Imprinting Solution: Together with the Matti Imprinting Solution, the M-Tower can be used as a standalone mono press. Either a simplex or duplex version can be implemented, suitable for web widths of up to 26″ with a print width of approx. 25″.

Inline, combined with Matti Imprinting Solution: This configuration is used to enable variable data printing on standard offset or flexo presses. Typically employed inline with legacy press.

Technical Data

- Transactional / Transpromo printing

- Security printing (MICR, fluorescent, others)

- Addressing

- Barcode printing

- Lottery tickets

- Labels

- Packaging

- Standalone operation as simplex or duplex mono press for book printing

- Integration into legacy presses, enabling them to print variable data

- Standalone operation as simplex or duplex mono press

- High volume continuous feed

- Eco friendly - low power consumption

- Ergonomic design with quick and simple paper thread up

- User-friendly operator interface with Touch Screen display

- Minimum ready-to-print time

- Small footprint

- Standard web width:

- 20.5” (520 mm)

- 26” (660mm)

- 30.7” (780mm)

Speed:- 500 ft/min (150 m/min)

- 1000 ft/min (300 m/min)

Paper weight: 55-180g/m^2

Electrical Power: 3x400VAC

- 20.5” (520 mm)

- 26” (660mm)

- 30.7” (780mm)

- 500 ft/min (150 m/min)

- 1000 ft/min (300 m/min)

Electrical Power: 3x400VAC

- Optional features include:

- High-Performance grayscale RIP

- IJPDS, IPDS, AFP workflow, depending on the inkjet writing

- Infeed / Outfeed module

- Web guide / cleaning unit

- Camera inspection system

- Color Register Control System

- High-Performance grayscale RIP

- IJPDS, IPDS, AFP workflow, depending on the inkjet writing

- Infeed / Outfeed module

- Web guide / cleaning unit

- Camera inspection system

- Color Register Control System