From ink formulation to production readiness

The Matti Technology AG Inkjet test lab supports customers / OEM customers and ink manufacturers to qualify and validate inkjet inks for use with different inkjet printheads and applications.

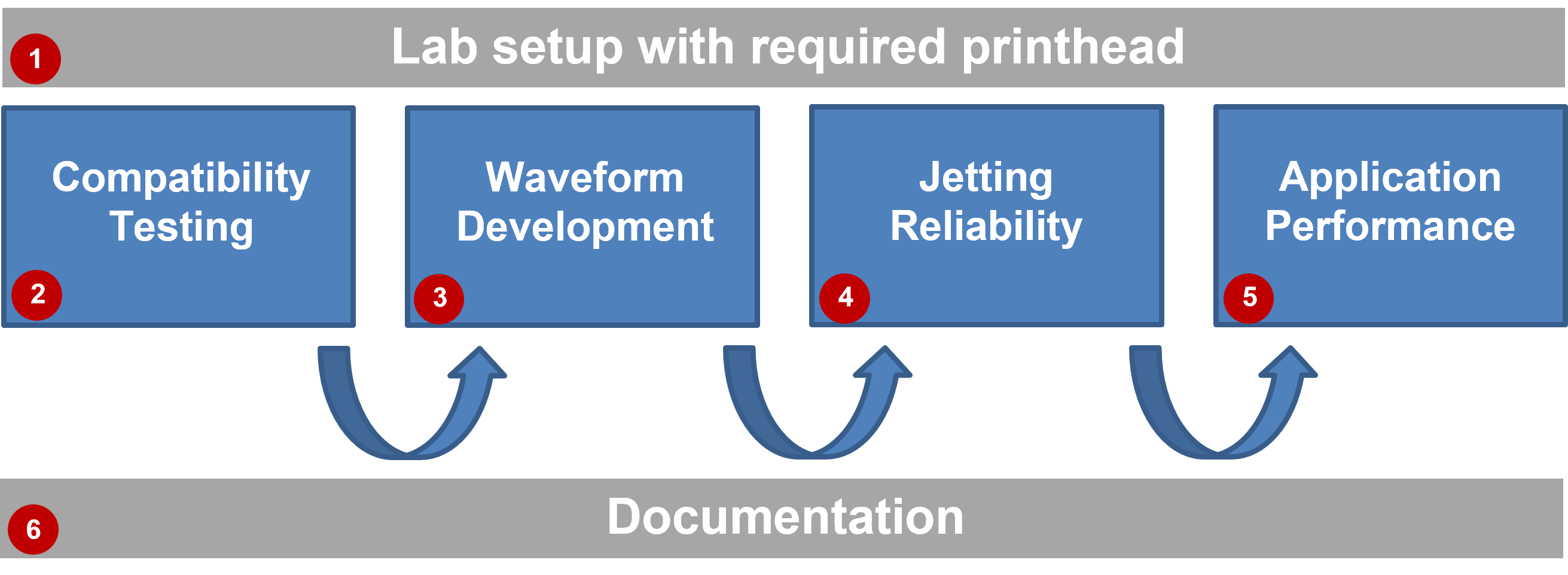

The tests performed follow a standardised process and is outlined below. Running through the process will give insights to the following questions:

- Is the ink compatible with a particular printhead?

- Does the ink jet reliably in a lab environment?

- Does the ink jet reliably in a simulated production process?

The following descriptions give some more detailed insights of the evaluation process and the different steps involved.

1: Lab Setup

According to the required inkjet head, the Matti lab is set up to electronically drive the head, supply fluids and to analyse ejected drops on the Dropwatcher system.

2: Compatibility Testing

Chemical compatibility is tested via the inkjet vendor chemical compatibility test procedure. Also, permissible materials are evaluated, should a machine be designed and built in the future.

3: Waveform Development

An initial waveform is developed with the goal to assess jetting properties of the ink on the dropwatcher system.

4: Jetting Reliabiliy

In this step, jetting reliability is assessed in a real-world application scenario on the machine testbed in the Matti lab at production speeds.

5: Application Performance

These tests give good information about the performance expectation of the ink in production environments. For the ink manufacturer the obtained results give valuable insights about the dynamic behaviour of the ink and required process parameters.

6: Documentation

All gained data and their interpretation is well documented to provide the best value to the ink manufacturer or OEM customer.