Your Shortcut To Best Ink Performance

The printability of a digital printing system depends also on factors other than the printing device itself. These include, but are not limited to, substrate / media, types and characteristics of the ink, drying systems, inkjet printhead technical parameters, inter-colour spacing and others.

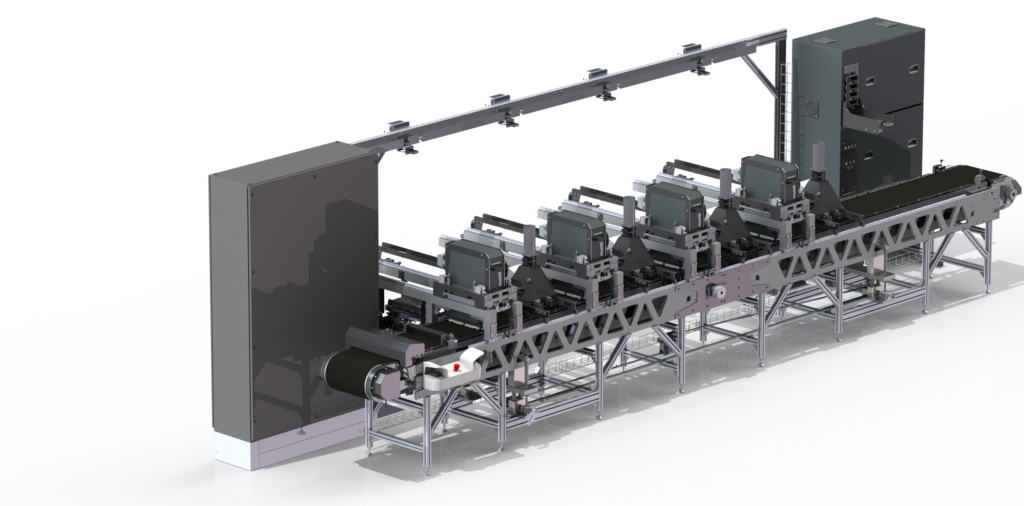

The Matti inkjet test platform has been designed around providing a test setup to evaluate these properties. It facilitates easy, useful and accurate direct comparisons of printing parameters, enabling precise assessment of process parameters, print functionality, print quality, paper / substrates testing, absorbency / printability, page scaling and colour conversion to proofing intricate design characteristics and acceptance testing.

The test stand is designed around a novel conveyor concept that provides a precise register delivered through multiple linear encoders, each placed at every single printbar in the system. This makes it easy to vary the spacing between the four (option: seven) colors.

The test platform is designed to work well and easily in a pure lab environment, But it can also be used to test production runs on an intermediate scale, before going onto production machinery with new ink. The solution will allow customers to:

- Test new inks

- Iterate between different inks quickly and efficiently

- Optimise production parameters (inter-color spacing, drying)

- Gain confidence with new inks before going onto production machinery, avoiding potential (expensive) damages and unforeseen downtime

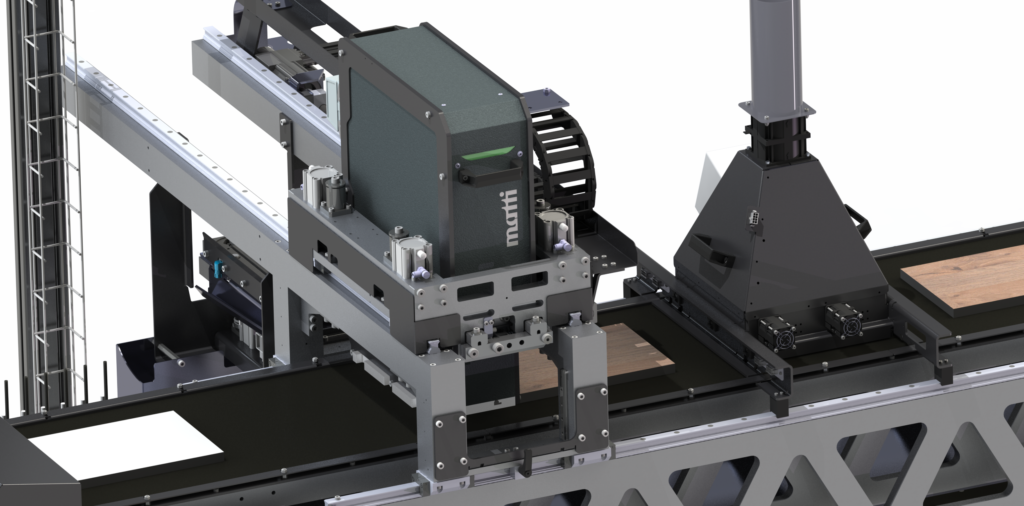

Printbars

Different applications require different combinations of inkjet printheads and inks. The test stand is designed with this in mind: printbars containing different inkjet heads can be exchanged easily. Testing and evaluating different inkjet heads, therefore, becomes possible, while performing all tests on the same platform.

To allow the best possible control of the ink properties, all critical conditioning such as temperature and pressure control is done in the printbars.

To facilitate maintenance and storage, the system comes with a fully automated cleaning & capping system. All maintenance tasks are performed automatically and according to the recommendations of the inkjet head vendor.

Conveyor

The smart conveyor makes it easy to use different substrates: paper, decor paper, foil, plastic film and others. The surface of the conveyor can be coated with different tackiness, depending on the substrate used.

The conveyor is digitally enabled, i.e. provides means to submit position information to the printbars, allowing precise, sub-10-micron registration over the entire length. The smart conveyor also allows moving the printbars easily, while all colors stay in perfect register.